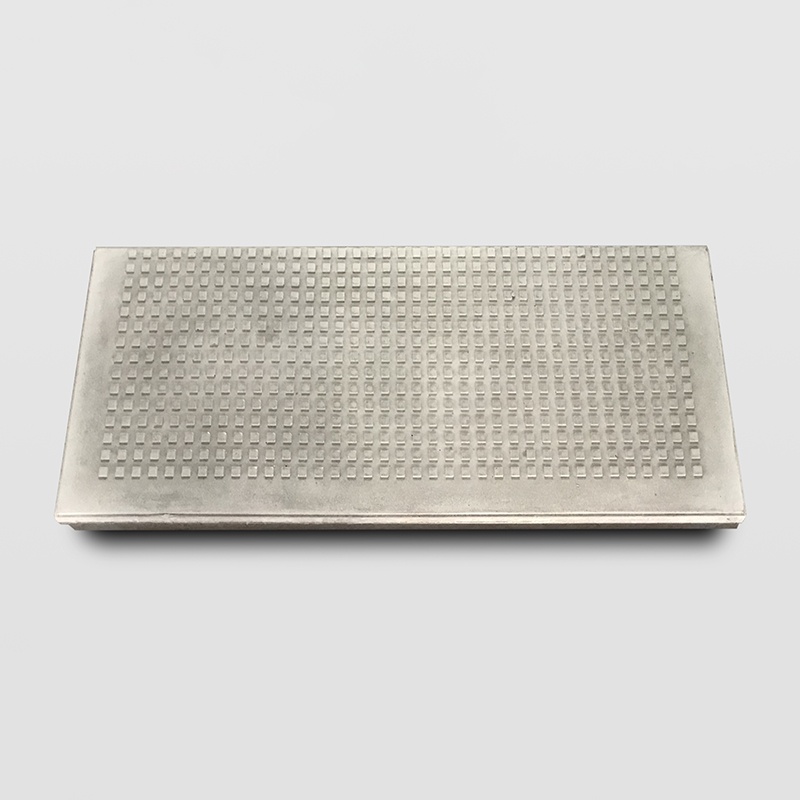

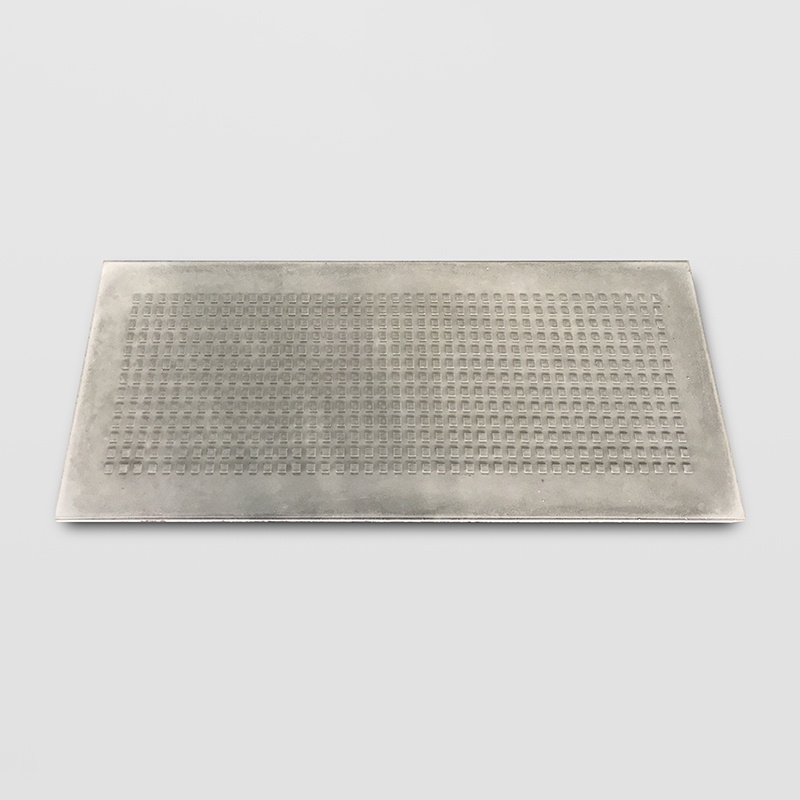

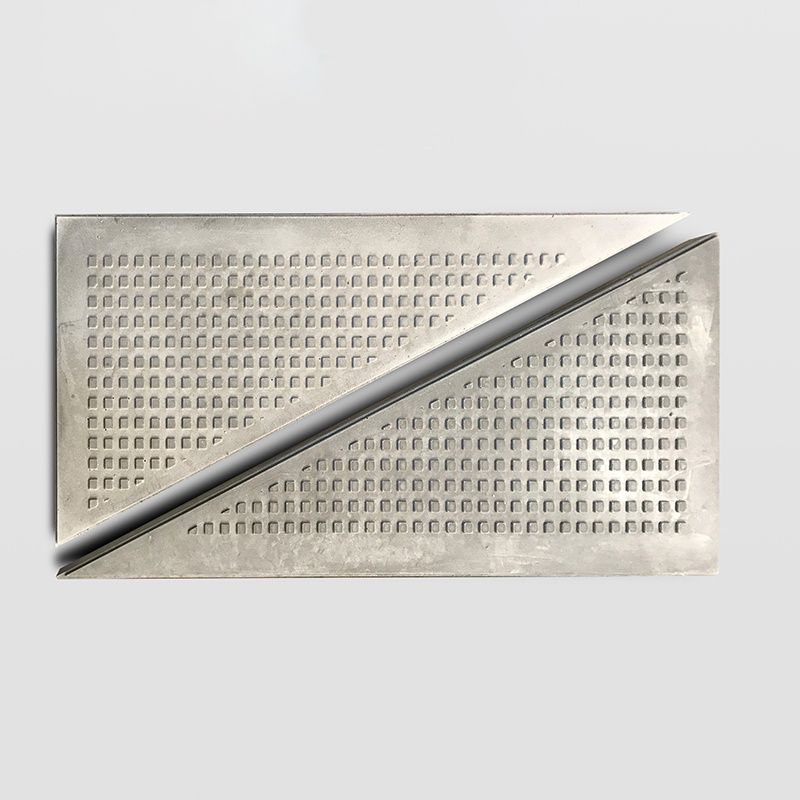

ANTI-SLID PRESSED SLABS

THIN COMPACT® SAFETY STONE are large dimension slabs, standardized for accessibility ramps. They combine strength and resistance with innovation and beauty in its different designs. The slabs have a texture that, in addition to providing an anti-slip grip, make an ideal surface for urban areas with heavy traffic, while adding a touch of decorative and contemporary design. The main purpose of installing these products on public areas is to facilitate the circulation of visually impaired people, people who need to use wheelchairs, as well as people with strollers. The slabs are equipped with integrated spacers to optimize their installation.

THIN COMPACT® SAFETY STONE® is a very high performance product and its manufacture includes:

- Premium gray cement CP 40

- Siliceous crushed rock

- Siliceous rock dust

FEATURES 1200x500

| Dimensions | Thickness ≈ | Weight ≈ Piece |

|---|---|---|

| 1200X500 mm | 5 cm | 60 |

FEATURES 1550x550

| Dimensions | Thickness ≈ | Weight ≈ piece |

|---|---|---|

| 1550X550 mm | 5 cm | 66 |

FEATURES TRIANGULAR 1200x500

| Dimensions | Thickness ≈ | Weight ≈ piece |

|---|---|---|

| 1200X500 mm | 5 cm | 22 |

WHEN HANDLING THE SLABS

- Move the material with the proper conditions and care.

- Avoid relocating pallets after unloading them from the truck in order to minimize possible impacts.

- Stack on smooth surfaces.

- Try to place the product in the area where it is to be installed in order to reduce the possibility of impacts during the change of location.

- If it is going to be stacked for a long period of time, it should be indoors.

- If the slabs are relocated, they should be left as they were shipped from the factory, face to face, in order to avoid damaging them.

- Avoid contact of the slabs with paint, rust, wood and wet cardboard so that the floor is not affected.

ASK THE SELLER FOR THE INSTALLATION INSTRUCTIONS

- It is very important that you follow the steps indicated in the Installation Instructions in order to preserve the quality of the product and to obtain the expected results..

IMPORTANT CONSIDERATIONS

- On common or concrete subfloors use the mixtures suggested in the Installation Instructions. Use adhesive on smoothed concrete.

- Paint the back side of the slab with a grout as indicated in the Installation Instructions; this facilitates the correct adhesion of the slabs.

- For grouting joints, use grout.

- If you are going to polish the mosaic tiles, leave the grout on the slab until the work is finished. This way, the dirt is left on the grout which will then be removed in the polishing process. This should be done every 3 to 4 hours to avoid cracking.